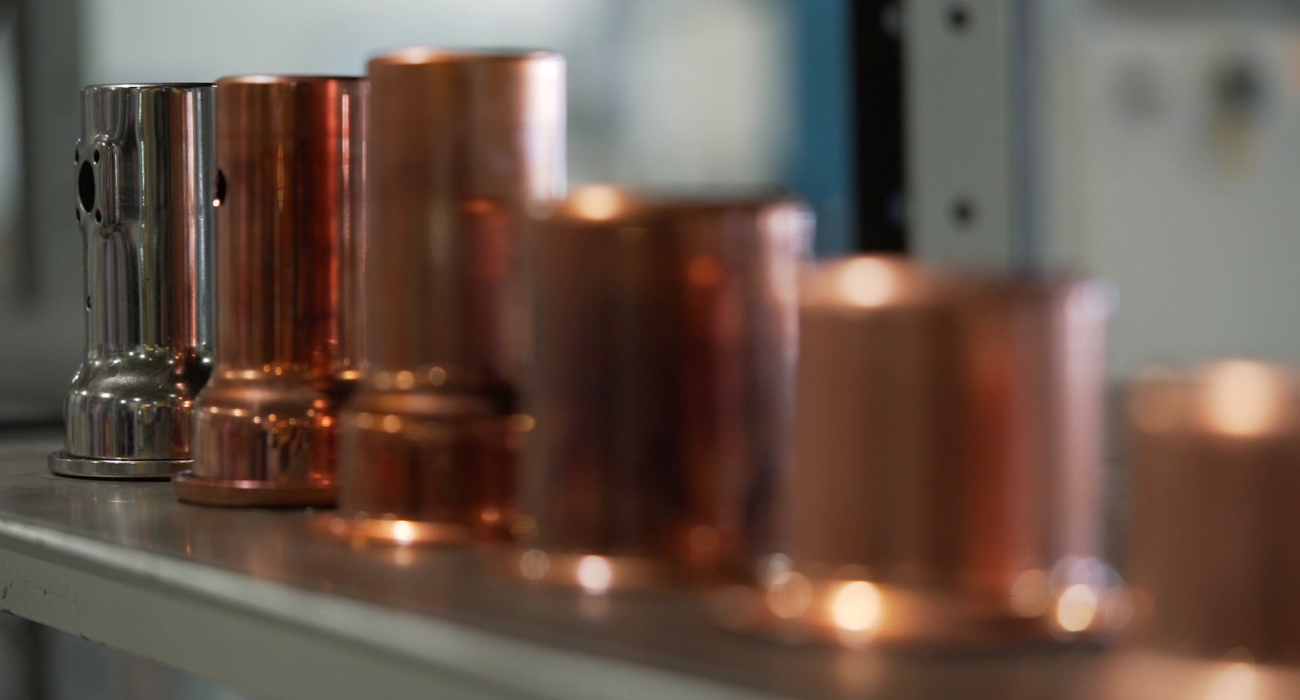

Deep drawing is a production technique with possibilities and potential, due to the usage of flat material (=blank) that is converted (in several deep drawing steps) into a 3D shape. Less material compared to a solid base volume is often also less weight. Cylindrical parts are obvious as examples but other shapes are also possible.

Deep drawing is a technique that, with a specific (re)design of a metal part, converts a part made by machining or milling into a solution with less material usage and lower costs.

KeyTec provides this technology in single step processing or progressive dies processing for large volumes.

Where tolerances, often given for special applications are very tight or specific surface condition is to be achieved, the deep drawn products are finished in house by either CNC as well as conventional machined operation.

A wide range of materials can be deepdrawn by KeyTec such as a variety of copper alloys, stainless steel alloys, specific Kovar alloys as well as Molybdenium.

Please find more about our deep drawing products in our solutions.