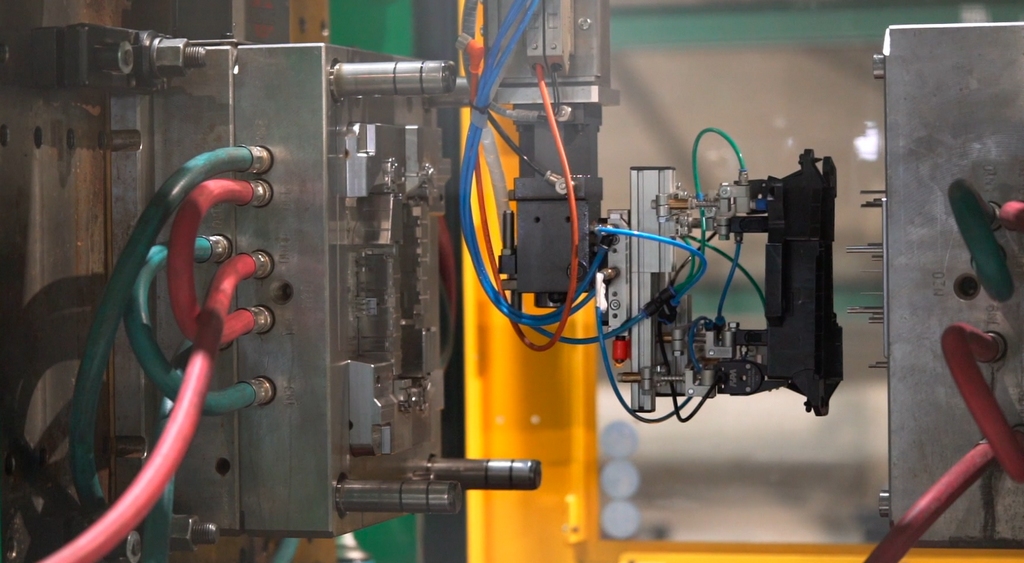

With the use of precision moulding tools operated on our premium brand moulding machines varying from 20 up to 250 Tons clamping force, KeyTec produces plastic parts. Well defined customer specific product designs are adopted and converted into stable processes resulting in high quality parts for industry, automotive and medical applications.

To support the specific requirements of the various applications, a wide range of plastics is processed at KeyTec, such as: PA, PPS, ABS, POM, PBT, PC, PPO, TPE, SEBS, but also LCP’s, PEEK, HSG and other specific thermal, electrical conductive and shielding polymers. The addition of additives gives these plastics specific properties such as protection against UV light, flame retardant (UL94 ..), (antibacterial) medical grades and strength through glass fibre filled material to achieve and overcome metal-like strenths in its parts at much lower costs than aluminium diecast and CNC grinding.

Parts can also be moulded under cleanroom conditions.

Please find more about our injection moulding products in our solutions.